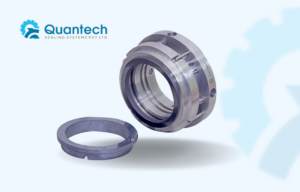

Mechanical Seals Repair

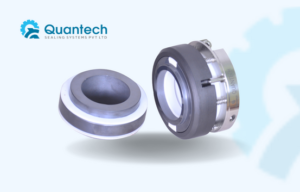

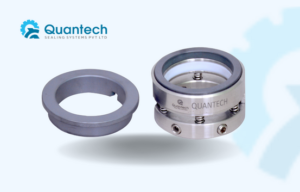

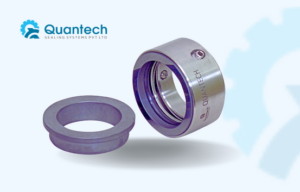

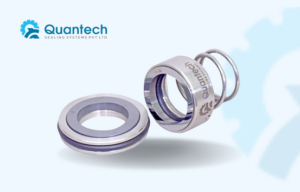

Quantech Sealing Systems is the top Mechanical seals repair service in India. Due to the increasing responsibility of maintenance personnel to reduce costs in the industry, Quantech Seals introduced the concept of Mechanical seals Refurbished service. With our technical strength, extensive experience, and sincere response, we reproduce standard mechanical seals such as large agitator, Mixer, Reactor mechanical seals and metal bellows mechanical seals with special technology to win the hearts of our customers. We have many prominent clients who are satisfied with our service.

Mechanical seal repair and overhaul is all about returning these components to a functional and reliable condition. Mechanical seals are essential to prevent fluid leakage in various industrial applications. Proper repair and refurbishment can extend life and reduce operational downtime. An overview of the mechanical seal repair and overhaul process is as follows:

Initial Assessment for Mechanical seals repair

- We Inspect mechanical seals to determine the extent of damage, wear and deterioration.

- Identify which components need to be repaired or replaced.

Dismantling

- We carefully disassemble the mechanical seal and document the process for easy assembly.

- Remove worn or damaged components such as seal faces, secondary seals, springs, o-rings, etc.

Clean and prepare components

- Thoroughly clean all components to remove dirt, debris and old lubricants.

- We Inspect components for signs of corrosion, pitting, or wear.

Component replacement

- We replace damaged or worn components with new original manufacturer parts.

- Make sure replacement parts are compatible with your specific mechanical seal model and application.

Lapping and Refinishing

- If necessary, lap to restore flatness and smoothness of the sealing surface. Use abrasives to achieve the desired surface finish.

Assembly

- Quantech seals reassemble the mechanical seal according to the manufacturer’s guidelines and ensure that the components are properly aligned and positioned.

- Apply a suitable lubricant to the components before assembly.

Testing

- Tests are performed to ensure that remanufactured mechanical seals are functioning properly and meeting required performance specifications.

- Check overall functionality for leaks and proper sealing.

Quality control and inspection of Mechanical seals

- A thorough inspection of remanufactured mechanical seals is performed to ensure all components are properly installed and working as intended.

- Make sure your seal meets quality standards and can function effectively in your application.

Documentation

- Keep detailed records of the repair and refurbishment process, including steps taken, parts replaced, and adjustments made.

Packaging and Returns

- We ensure that the remanufactured mechanical seal is properly packaged for safe return to the customer.

- Provide customers with clear instructions for installation and maintenance.

Customer service

- we provide guidance and assistance to customers on proper installation, operation and maintenance of remanufactured mechanical seals.

It is important to note that repair and refurbishment details may vary depending on the mechanical seal type, industry and manufacturer’s recommendations. If you are unfamiliar with mechanical seal repairs, it is recommended that you consult our engineers to ensure that the repair is performed accurately and effectively.

Proper installation, maintenance and monitoring are required to ensure the effectiveness of mechanical seals and prevent leakage, Mechanical seals Refurbished. They are widely used in industrial sites where leak prevention is essential to maintain operational efficiency, prevent contamination, and ensure worker safety.

Quantech Sealing Systems is a leading Mechanical Seals repair in India. Mechanical seals are devices used to prevent the leakage of fluids, such as liquids or gases, from rotating machinery, such as pumps, compressors, and mixers. They are commonly used in various industries to maintain a secure and leak-free environment for processes involving liquids or gases. Mechanical seals play a crucial role in maintaining equipment efficiency, reducing maintenance needs, and preventing environmental contamination.

The main purpose of mechanical seals is to create a barrier that prevents fluids, such as liquids and gases, from leaking out of a device. This ensures efficient machine operation and prevents environmental pollution, product loss or equipment damage.

Mechanical Seal Supplier in India

Quantech Sealing System is a Top and Best Mechanical Seals Manufacturers and Exporter in Jharkhand. Our major Mechanical Seals supply in Jharkhand’s industrial areas include those located in Quantech Seals is a leading Mechanical Seals manufacturer in India. We are the team of fresh and active engineers, with 12 years of experience in designing, manufacturing and repairing of Mechanical Seals, Oil Seals and Pumps.

Mechanical seals Refurbished services is the important one for all Industrial equipment companies, we have happy clients from different industries like power plant, pharmaceuticals, food processing, chemicals, water, oil & gas, mining, paper & more, with premier quality, cost effective and security principles. Quantech Seals is expressive enough to tell about our domain which contains manufacturing, supplying and exporting of Single Spring Seal, Multi Spring Seal, Bellow Seal, Cartridge Seal, Reactor Seal, Mixer Seal, Double Cartridge Mounted Seal, Double mechanical seals and many more.

Mechanical seals have a wide range of applications across various industries due to their ability to prevent leakage and maintain a secure seal in rotating machinery. Some common uses of mechanical seals include:

Mechanical Seals manufacturer in India

Quantech Sealing System is one of the main mechanical seal Manufacturer in India. We deliver high-quality mechanical seal products, and have many clients in India. Separate rings are installed on the shaft and machine housing to allow minimal leakage of the liquid. To ensure this, each part is fabricated according to a precise design. Quantech Seals provides the best mechanical seal solutions on time to customers. Quantech Manufacturer and repair for Mechanical Seals in India, and major cities serve in Andra Pradesh, Telangana, Gujarat, Uttar Pradesh, Rajasthan, Haryana, Punjab, Jammu and Kashmir, Maharashtra, Tamil Nadu, Karnataka, Delhi, Jharkhand, Chhattisgarh, West Bengal, Assam, Odisha, Kerala, Bihar Regions. We make use of the best quality raw materials which are sourced from reliable vendors worldwide and assure quality control checks at each stage of production. We have technical service division supported by qualified personnel and prompt after-sales service, including free installation assistance and satisfactory troubleshooting with faster delivery. We manufacture reliable, precision range, and durability of Mechanical Seals for Pumps, Compressors, Agitators, Mixers, Reactors, Dyeing Machines, and all other equipment having rotating shafts.