Mechanical Seals Manufacturer in Delhi

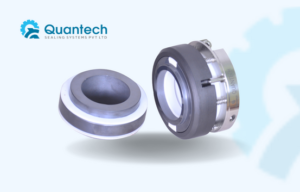

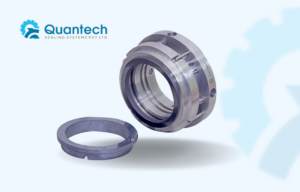

Quantech Sealing Systems is a leading Mechanical Seals manufacturer in Delhi. A mechanical seal is a device that prevents fluid leakage between two rotating or stationary components, typically in pumps, mixers, and other rotating equipment. This helps maintain a seal between the shaft or spindle and the body or housing of the device. Mechanical seal consists of several key components i.e., Stationary Face, Rotating Face, Secondary Sealing Elements, Springs, Seal Gland or Housing etc.,

The main purpose of mechanical seals is to create a barrier that prevents fluids, such as liquids and gases, from leaking out of a device. This ensures efficient machine operation and prevents environmental pollution, product loss or equipment damage.

Various Types of Mechanical Seal

Quantech Sealing System is a Top and Best Mechanical Seals Manufacturers and Exporter in Delhi. Our major Mechanical Seals supply in Delhi’s industrial areas include those located in Narela, Bawana, Rani Khera, Bapraula, Jhilmil, Patparganj, Wazirpur, Rohtak Road, Mangolpuri, Rani Jhasi Road, Mayapuri, Tilak Nagar, Najafgarh Road, Okhla, Lawrence Road, Udyog Nagar, Kirti Nagar, Badli, etc., other cities of New Delhi like, Noida, Gurugram, Faridabad, Greater Noida, Ghaziabad, Haryana, etc., Quantech Seals is a leading Mechanical Seals manufacturer in India. We are the team of fresh and active engineers, with 12 years of experience in designing, manufacturing and repairing of Mechanical Seals, Oil Seals and Pumps.

We have happy clients from different industries like power plant, pharmaceuticals, food processing, chemicals, water, oil & gas, mining, paper & more, with premier quality, cost effective and security principles. Quantech Seals is expressive enough to tell about our domain which contains manufacturing, supplying and exporting of Single Spring Seal, Multi Spring Seal, Bellow Seal, Cartridge Seal, Reactor Seal, Mixer Seal, Double Cartridge Mounted Seal, Double mechanical seals and many more.

Single Mechanical Seal: A single mechanical seal consists of two sealing faces, a fixed face and a rotating face. The most basic type of mechanical seal, used in a wide range of applications.

Double Mechanical Seal: A double mechanical seal, also known as a double mechanical seal, consists of two sets of sealing faces. Provides an additional layer of protection by forming a secondary barrier between the process fluid and the environment. Often used in applications where no leakage is allowed.

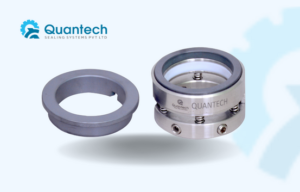

Cartridge Mechanical Seals: Cartridge mechanical seals are pre-assembled units that include all the components required for a mechanical seal such as sealing faces, springs and gland plates. Cartridge seals are easy to install and replace, reducing maintenance downtime.

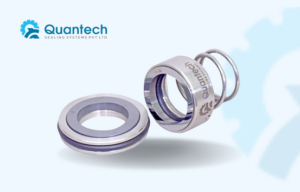

Pusher Mechanical Seal: Pusher Mechanical Seals use springs to maintain contact between the sealing faces. Springs compress the seal faces to compensate for wear and maintain a uniform seal. This type of seal is often used in applications with high shaft speeds or where axial travel is required.

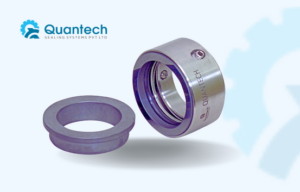

Non-Pusher Mechanical Seal: The Non-Pusher Mechanical Seal does not have a direct spring pressure on the seal face. Instead, a secondary sealing element such as an O-ring or bellows provides the force necessary to maintain contact between the sealing faces. This design is often used in applications where pumped fluid can clog or contaminate the springs.

Balanced Mechanical Seals: Balanced mechanical seals are designed to minimize the effects of hydraulic forces on the seal faces. Features include hydraulic balance chambers and additional sealing elements to counteract the effects of pressure differentials. Balanced seals are typically used in applications with large pressure differentials or where the process fluid contains solids or abrasive particles.

Delhi has several industrial areas where you will find specialty stores and distributors of industrial equipment and components. If you visit areas such as the Okhla Industrial Area, Bawana Industrial Area, or Mayapuri Industrial Area, you may have the opportunity to find suppliers of mechanical seals.

Mechanical Seals manufacturer in India

Quantech Sealing System is one of the main mechanical seal Exporter in New Delhi. We deliver high-quality mechanical seal products, and have many clients in New Delhi. Separate rings are installed on the shaft and machine housing to allow minimal leakage of the liquid. To ensure this, each part is fabricated according to a precise design. Quantech Seals provides the best mechanical seal solutions on time to customers. Quantech Manufacturer and repair for Mechanical Seals in Delhi, and also in Gujarat, Uttar Pradesh, Rajasthan, Haryana, Punjab, Jammu and Kashmir Regions. We make use of the best quality raw materials which are sourced from reliable vendors worldwide and assure quality control checks at each stage of production. We have technical service division supported by qualified personnel and prompt after-sales service, including free installation assistance and satisfactory troubleshooting with faster delivery. We manufacture reliable, precision range, and durability of Mechanical Seals for Pumps, Compressors, Agitators, Mixers, Reactors, Dyeing Machines, and all other equipment having rotating shafts.